Application of Mica Insulation Materials in BGA Rework Stations

Application of Mica Insulation Materials in BGA Rework Stations

What is Mica? What is the specification and parameters of mica?

Mica is a naturally occurring mineral that belongs to the group of silicate minerals. It is known for its distinct layered structure and exceptional combination of physical, chemical, and thermal properties. Mica is widely used in various industries, including electronics, cosmetics, construction, and more, due to its heat resistance, electrical insulation, and other beneficial qualities.There are several types of mica-based insulating material available in the market, including:

1. Muscovite mica: A type of mica-based insulating material that is known for its high dielectric strength, good thermal stability, and excellent electrical and mechanical properties. it working temperature about 500°, peaks of 700°

2. Phlogopite mica: A type of mica-based insulating material that contains a higher percentage of elements such as iron, magnesium, and aluminum. Phlogopite mica insulators are known for their excellent thermal resistance and high-temperature stability. It working temperature around 800°,peaks of 1000°。

3. Synthetic mica: A type of mica that is produced by chemical synthesis. Synthetic mica insulators have excellent electrical and thermal insulation properties and are often used in high-temperature applications. It working temperature 1000° peaks of 1200°

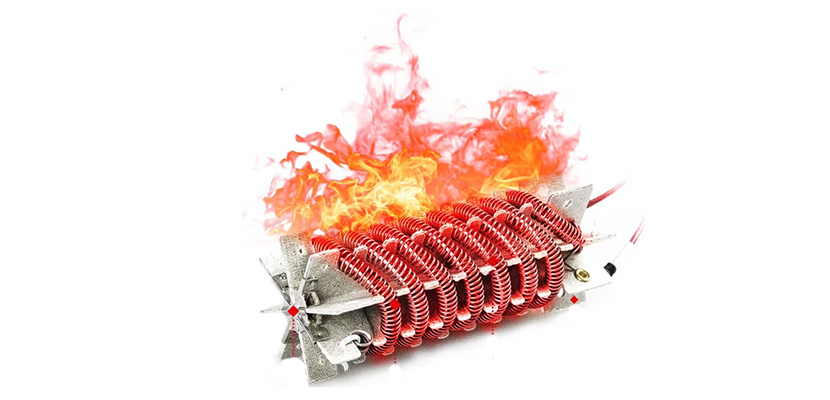

Mica insulation materials play a crucial role in various industrial applications due to their exceptional electrical, thermal, and mechanical properties. In the context of BGA rework stations, mica-based products find essential application in ensuring reliable and effective rework processes for electronic components, particularly BGAs, which are widely used in modern electronics.

What is the key characteristics that make mica suitable for BGA rework stations?

Thermal Insulation: Mica has excellent thermal insulating properties, which help protect sensitive electronic components from heat damage during the rework process.

Electrical Insulation: Mica's high dielectric strength prevents electrical leakage and ensures that the rework process does not cause unintended electrical connections.

Mechanical Stability: Mica products maintain their structural integrity even at elevated temperatures, preventing deformation or cracking during the rework process.

Chemical Inertness: Mica is resistant to many chemicals, which is crucial when working with various soldering materials and fluxes.

Mica insulation materials serve as essential components in BGA rework stations, providing thermal and electrical insulation to safeguard sensitive electronic components during rework processes. Their thermal stability, dielectric properties, and mechanical durability make them valuable tools for efficient and reliable electronic repair and assembly.

Advantages and Benefits:The use of mica insulation materials in BGA rework stations offers several advantages:

Reliability: Ensures that components are protected from excessive heat and prevents damage during rework, increasing the overall reliability of the electronics.

Efficiency: Facilitates smoother rework processes by allowing precise control of heat application.

Versatility: Mica products can be tailored to various shapes and sizes, making them adaptable to different electronic components.

Longevity: Mica's stability at high temperatures ensures that the insulation remains effective over multiple rework cycles.

Latest News

Contact Us

Tel: +86-13184770996

E-mail: info@goldenmica.com