Iron and Steel

Mica insulators are indeed used in various industries, including the steel industry, due to their unique electrical, thermal, and mechanical properties. In the steel industry, mica insulators find applications primarily in electric arc furnaces and induction furnaces. Let's explore why and how mica insulators are used in the steel industry:

1. High Temperature Resistance: Electric arc furnaces and induction furnaces in the steel industry operate at extremely high temperatures. Mica is a naturally occurring mineral that can withstand these high temperatures without melting, deforming, or emitting harmful fumes. This makes mica a suitable material for insulating components within these furnaces.

2. Electrical Insulation: Mica is an excellent electrical insulator. In electric arc and induction furnaces, there are various electrical components and connections that need to be insulated to prevent short circuits and ensure safe operation. Mica insulators are used to isolate electrical elements, such as heating elements and electrodes, from the surrounding metal structure.

3. Thermal Insulation: Mica has good thermal insulating properties. In the steel industry, where furnaces generate intense heat, it's crucial to minimize heat loss to the surroundings. Mica insulators are used to create barriers that help contain and direct the heat within the furnace, enhancing energy efficiency and overall furnace performance.

4. Dielectric Strength: Mica has a high dielectric strength, meaning it can withstand high voltage differences without breaking down. In electric arc and induction furnaces, there can be significant voltage differentials between various components. Mica insulators prevent electrical arcing and breakdowns by maintaining a barrier between these components.

5. Mechanical Strength: Mica sheets can be reinforced with materials like glass fibers or resins to enhance their mechanical strength and durability. This is important in industrial applications where components might be subject to mechanical stress or vibrations.

How Mica Insulators Are Used in Electric Arc Furnace and Induction Furnaces?

Mica insulators are integrated into the design of electric arc and induction furnaces in several ways:

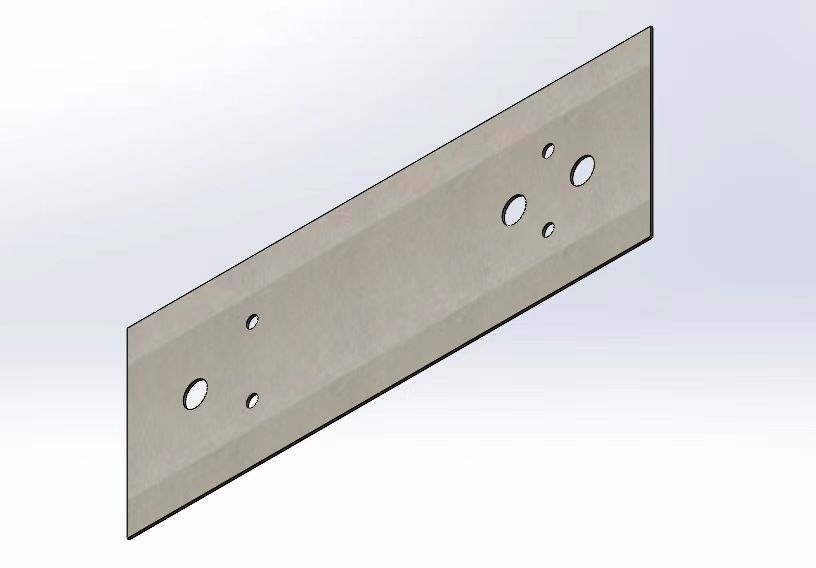

Insulating Plates: Mica sheets or plates are used to create barriers between different furnace components, preventing direct contact and minimizing heat and electrical transfer.

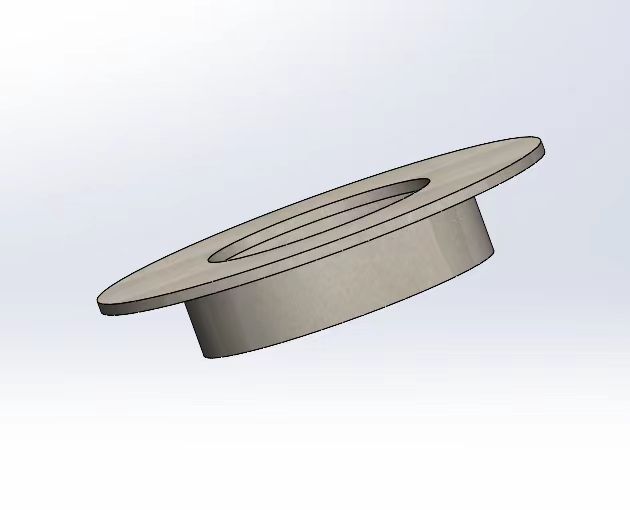

Gaskets and Seals: Mica-based gaskets and seals are used to create airtight and heat-resistant seals at various joints and openings in the furnace, preventing heat loss and maintaining the furnace's efficiency.

Spacer Blocks: Mica insulators can be used as spacer blocks between electrodes and other conductive elements to prevent electrical short circuits.

Electrode Insulation: Mica insulators are used to electrically insulate the electrodes that supply the electric current to the furnace, preventing unwanted electrical discharge.

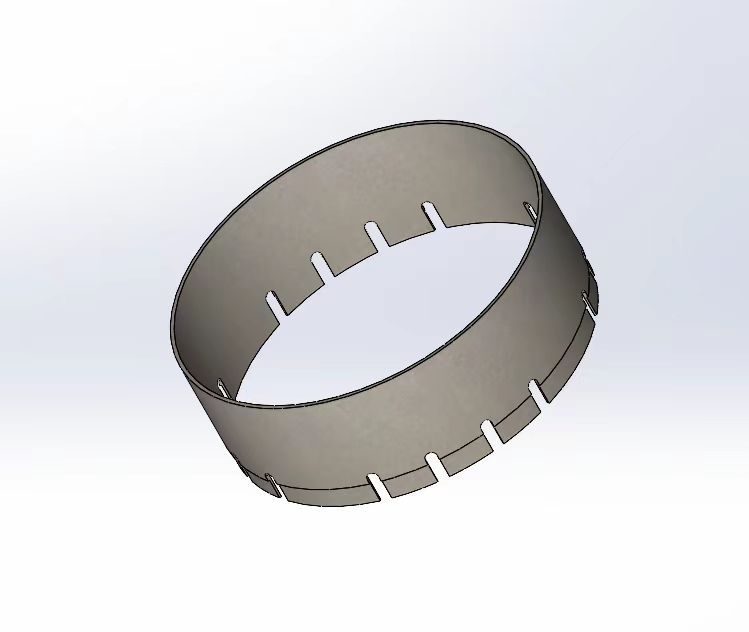

Coil Insulation: In induction furnaces, mica is often used to insulate the coils that generate the electromagnetic field for heating the metal.

In conclusion, mica insulators are essential components in the steel industry, particularly in electric arc and induction furnaces, where their high temperature resistance, electrical insulation, thermal insulation, dielectric strength, and mechanical durability play a crucial role in ensuring efficient and safe furnace operation.

Industries

Contact Us

Tel: +86-13184770996

E-mail: info@goldenmica.com