Aluminum

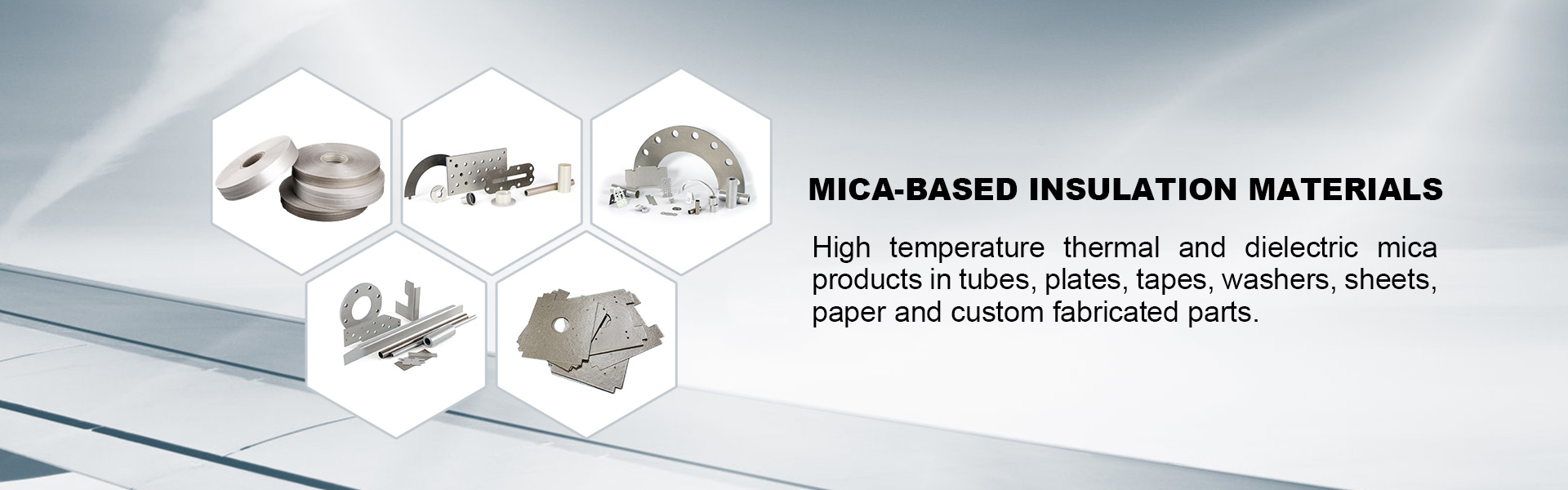

In the world of heavy industry, where extreme temperatures, high voltages, and corrosive environments are the norm, finding the right materials that can withstand these conditions is crucial. One such material that has stood the test of time in the aluminum industry is mica. Mica sheets, with their exceptional electrical insulation, thermal resistance, and chemical inertness, have found a significant and diverse range of applications within aluminum smelting and refining processes.

The aluminum industry is known for its energy-intensive processes and the need for advanced technologies that can handle the intense conditions involved in smelting and refining aluminum ore. The primary goal is to achieve optimal energy efficiency, safety, and product quality. This is where mica sheets enter the scene as a critical component that supports these objectives.

1. Electrical Insulation

One of the most critical applications of mica sheets in the aluminum industry is their use as electrical insulators. Aluminum smelting involves high-voltage equipment, including switches, circuit breakers, and transformers. Mica's excellent dielectric strength and electrical resistance make it an ideal material for insulating and isolating these components, preventing arcing, short-circuits, and electrical accidents.

2. Thermal Insulation

Extreme temperatures are the hallmark of aluminum smelting. Mica's natural ability to withstand heat and provide thermal insulation is invaluable in maintaining stable operating conditions. By using mica sheets to insulate heating elements and protect equipment from excessive heat, the industry can prevent heat loss and ensure the longevity of crucial components.

3. Corrosion Resistance

The harsh chemicals present in the aluminum smelting environment can corrode and degrade materials over time. Mica's chemical inertness makes it an excellent choice for insulating materials that are in direct contact with corrosive substances. This characteristic ensures the longevity of equipment and reduces maintenance requirements, ultimately contributing to operational efficiency.

4. Component Support and Isolation

Mica sheets are also used for supporting and isolating electrical components within the aluminum smelting process. These components, such as bus bars and connectors, need to be securely mounted while preventing any electrical leakage or short-circuiting. Mica's non-conductive properties and mechanical strength make it a reliable choice for these applications.

5. Gaskets and Seals

In an environment where leaks and contamination can lead to costly disruptions, mica sheets find application as gasket materials. They are used to create seals between different parts of equipment, ensuring that heat, electricity, and materials are contained as intended. This helps maintain operational efficiency and safety.

Conclusion

Mica sheets have proven themselves as indispensable assets within the aluminum industry. Their versatility in providing electrical insulation, thermal resistance, and corrosion protection aligns perfectly with the industry's demands for efficiency, safety, and durability. As the aluminum industry continues to evolve, mica sheets will undoubtedly remain a steadfast ally, contributing to the production of this vital metal while upholding high standards of performance and reliability.

The aluminum industry is known for its energy-intensive processes and the need for advanced technologies that can handle the intense conditions involved in smelting and refining aluminum ore. The primary goal is to achieve optimal energy efficiency, safety, and product quality. This is where mica sheets enter the scene as a critical component that supports these objectives.

1. Electrical Insulation

One of the most critical applications of mica sheets in the aluminum industry is their use as electrical insulators. Aluminum smelting involves high-voltage equipment, including switches, circuit breakers, and transformers. Mica's excellent dielectric strength and electrical resistance make it an ideal material for insulating and isolating these components, preventing arcing, short-circuits, and electrical accidents.

2. Thermal Insulation

Extreme temperatures are the hallmark of aluminum smelting. Mica's natural ability to withstand heat and provide thermal insulation is invaluable in maintaining stable operating conditions. By using mica sheets to insulate heating elements and protect equipment from excessive heat, the industry can prevent heat loss and ensure the longevity of crucial components.

3. Corrosion Resistance

The harsh chemicals present in the aluminum smelting environment can corrode and degrade materials over time. Mica's chemical inertness makes it an excellent choice for insulating materials that are in direct contact with corrosive substances. This characteristic ensures the longevity of equipment and reduces maintenance requirements, ultimately contributing to operational efficiency.

4. Component Support and Isolation

Mica sheets are also used for supporting and isolating electrical components within the aluminum smelting process. These components, such as bus bars and connectors, need to be securely mounted while preventing any electrical leakage or short-circuiting. Mica's non-conductive properties and mechanical strength make it a reliable choice for these applications.

5. Gaskets and Seals

In an environment where leaks and contamination can lead to costly disruptions, mica sheets find application as gasket materials. They are used to create seals between different parts of equipment, ensuring that heat, electricity, and materials are contained as intended. This helps maintain operational efficiency and safety.

Conclusion

Mica sheets have proven themselves as indispensable assets within the aluminum industry. Their versatility in providing electrical insulation, thermal resistance, and corrosion protection aligns perfectly with the industry's demands for efficiency, safety, and durability. As the aluminum industry continues to evolve, mica sheets will undoubtedly remain a steadfast ally, contributing to the production of this vital metal while upholding high standards of performance and reliability.

Industries

Contact Us

Tel: +86-13184770996

E-mail: info@goldenmica.com