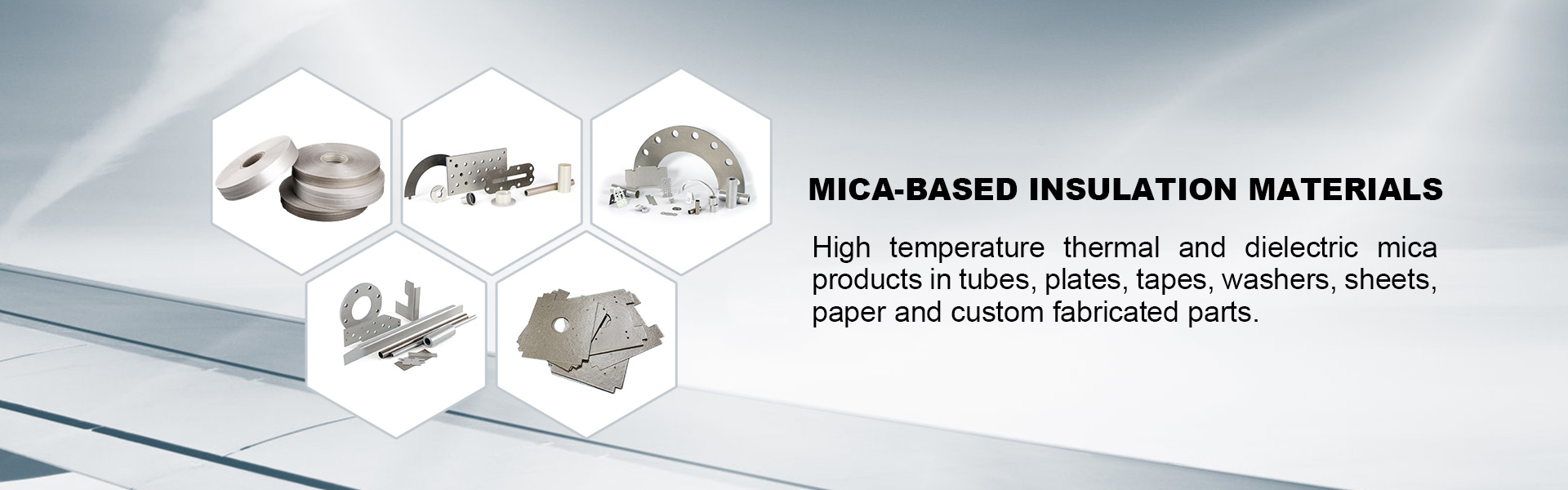

Mica Heaters- Solutions for Hot-Air Rework Stations | Goldenmica

Enhancing Precision and Efficiency: The Application of Mica Heaters in Hot-Air Rework Stations

In the dynamic world of electronics, the demand for precision and efficiency in repairing and reworking components is paramount. Hot-air rework stations have emerged as essential tools in this endeavor, enabling the delicate task of soldering and desoldering electronic components. Mica heaters, with their exceptional thermal properties and versatility, have proven to be invaluable additions to hot-air rework stations, revolutionizing the rework process.

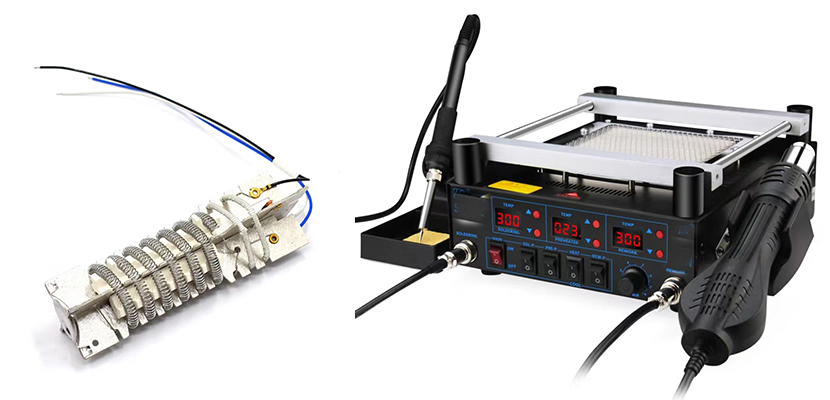

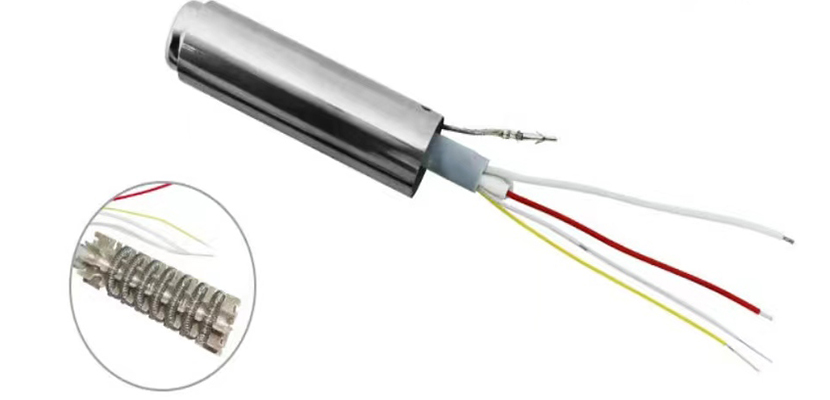

Mica Heaters:

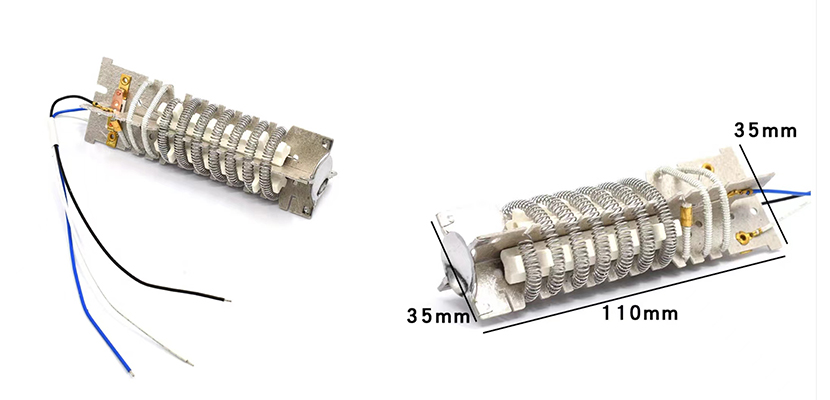

Mica heaters are heating elements composed of mica insulation sheets sandwiched between resistive wires. Mica, a naturally occurring mineral known for its outstanding thermal and electrical insulating properties, serves as an ideal base for these heaters. The resistive wires, usually made of materials like nichrome, are wound around the mica sheets, producing a flexible and efficient heating element. Mica heaters are renowned for their rapid heat transfer capabilities, uniform temperature distribution, and resistance to high temperatures.

Precision and Control in Rework:

One of the most significant advantages of mica heaters is their ability to provide precise and controlled heating. In the context of hot-air rework stations, where precise temperature control is crucial, mica heaters excel. The even distribution of heat across the surface of the heater ensures consistent heating of the air stream, allowing technicians to work with accuracy and confidence. This precision is essential when soldering or desoldering intricate components, preventing damage due to temperature fluctuations.

Efficiency and Rapid Response:

Mica heaters are known for their rapid response time, reaching the desired temperature quickly and efficiently. In the context of hot-air rework, this attribute translates into reduced downtime and increased productivity. Technicians can swiftly transition between different temperature settings, optimizing the rework process for various components and tasks. The efficient heat transfer of mica heaters results in shorter warm-up periods, allowing for faster rework operations.

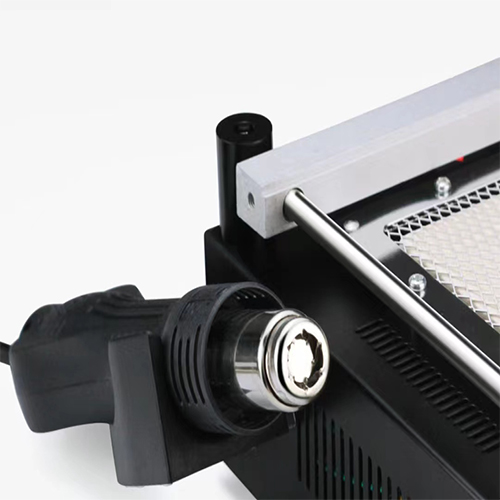

Safety and Reliability:

Safety is paramount in any technical operation, and mica heaters contribute significantly to the safety of hot-air rework stations. Their excellent insulation properties prevent excessive heat from radiating to the exterior, reducing the risk of accidental burns or damage to nearby components. Mica heaters' reliable performance and longevity ensure that rework tasks can be undertaken consistently without the concern of equipment failure.

Conclusion:

The integration of mica heaters into hot-air rework stations marks a significant advancement in the field of electronics rework. These heaters combine precision, efficiency, and safety, addressing the critical requirements of delicate rework tasks. With their ability to provide uniform and controlled heating, rapid response times, and robust insulation properties, mica heaters enhance the capabilities of hot-air rework stations and contribute to the overall advancement of the electronics industry.

Latest News

Contact Us

Tel: +86-13184770996

E-mail: info@goldenmica.com